Removable Insulation Blankets with Heating Elements

This article was written by Will Jones, an expert at Thermaxx Jackets

There are instances in which it is appropriate to fit a removable insulation jacket with a heating element such as heat trace or silicone heat pads. The circumstances can vary from the common application such as piping to the extremely special application. Regardless, the goal is the same: Keep a fluid or component warm.

The most common uses of Heat Trace cable in a removable insulation jacket has to do with freeze protection of piping and valves. However, the fluid within the piping could have a requirement of being at a temperature well above ambient temperature, 140°F or higher.

Common Applications for Pipe Heating Blankets

Thermaxx has made many jackets for each type of application. Whether the goal is freeze protection or constant fluid temperature, the fluid temperature, desired temperature and the ambient temperature must be considered. Common applications for pipe heater blankets include:

- Manufacturing operations (including process gases and materials)

- Industrial services

- Oilfield work

- Outdoor pipes and waterlines

- Dairy and agriculture industries

- Mining operations

- Water treatment plants

- Power generation

- Water meters

- Outdoor steam traps

- Backflow preventers

- Commercial natural gas flow meters

How to Decide What Insulation Blankets You Need

The first step is to calculate the heat loss, this can be per lineal foot or per square foot, the important thing is that we know how much heat is lost so we can calculate the wattage of the heat trace required.

Typically, a self-limiting heat trace cable is used, the reason being that the upper temperature of the heat trace cable is lower than the maximum temperature of the hot side or inside cloth material. The hot side material for an insulation jacket with heat trace is usually either a 15.5 oz./sq.yd. Silicone coated fiberglass cloth or in the case of temperatures above 400°F a Teflon® coated fiberglass cloth is used for temperatures up to 600°F.

As shown in the pictures below, the engineer wanted the heat trace cable at 22.5° from the bottom center for the purpose of freeze protection of condensate in a pipe.

Keeping a fluid within a valve at a temperature higher than ambient requires the same 3EPlus calculation to determine the amount of footage at a given watt/foot rating of heat trace cable. The picture below

shows a removable insulation jacket with heating cables for a specialized valve in a production environment. This valve is small, it is in an enclosed air tight cabinet that has an extremely hazardous gas flowing in the line.

|

|

|

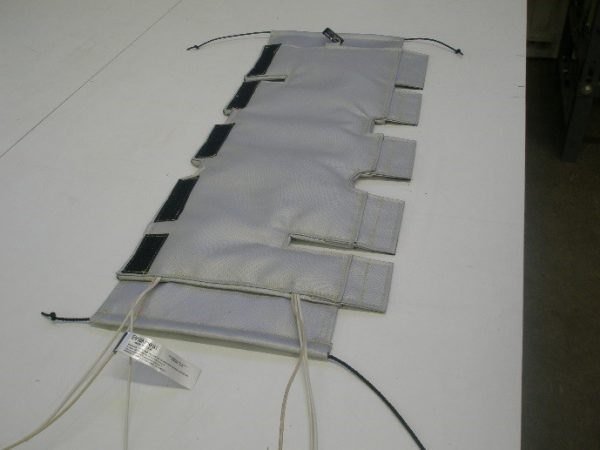

The wattage requirement of the heat trace cable sewn into the removable insulation jacket required a very specific pattern to get the required footage of heating element within the removable insulation jacket. Once designed, the cable was fed through loops that were sewn on the inside of the hot side cloth and fastened. Many loop locations were required to hold the heating element or heat trace cable in place within the material shown to the right.

Typically when a large valve, such as a gate, globe or control valve requires a heating element or heat trace cable within the insulation jacket, we must defer to the advice of the many companies that manufacture and supply heating elements or heat trace cable. They advise that because of the irregular shape of the component, the heating element will not make direct contact with the body of the valve. This is undesired because now the heat trace cable will be heating air between the insulation jacket and the body of the component. Air is a great insulator and the heat or BTU’s required to prevent freezing or keep the fluid within the valve at a given temperature will not be able to perform the required job. Heating elements in removable insulation jackets should not be used in this application.

In cases such as these we recommend that the heat trace cable or heating element be installed directly on the component eliminating any chance of heating air and not the component. After the heat trace cable is installed properly, the removable insulation blanket or jacket is installed on the component.

A great application for installing the heating pad or element either inside the removable insulation jacket or directly on the surface of the component is for heating a barrel or tank of some sort. This application lends itself to the use of a silicone heating pad. The pad can be quite small, or quite large. We have used pads to heat 55 or 85-gallon drums, tanks with water or condensate in them, a tank with an air-gas that couldn’t get cold.

|

|

Silicone pads with a thermostat were placed at each quadrant of the barrel. Then the removable insulation jacket is placed over the silicone heating pad.

Anytime a heating element or heat trace cable is used in conjunction with a removable insulation jacket there is one thought to keep in mind. That thought is the heat trace cable, the silicone heating pad or the heating element will fail before the removable insulation jacket fails (at least with a Thermaxx Jacket). If the heat trace cable or heating element is sewn directly into the jacket the entire jacket will be replaced, not just the heating element or heat trace cable.

This is why today at Thermaxx Jackets when we use heat trace cable or a heating element or pad, the component is held onto the inside of the jacket using belt loops or straps. Now when the heating element fails, only the heating element must be replaced, not the entire jacket. Thermaxx is cognizant of our customers desire to purchase the best product at the best price that will do the job for a long, long time.

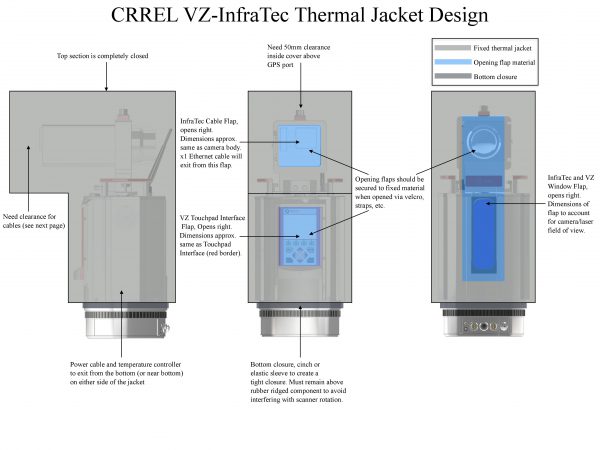

Thermaxx was selected to design and build a removable insulation jacket with silicone heating pads that was used as a housing for an infrared camera that was used in Antarctica! The The person leading the expedition wrote back to us and reported,

“I have just arrived back from Antarctica. The jacket worked very well with the system, thank you for checking up. I did make a few modifications so that the jacket fit tighter on the scanner (designed nylon standoffs that bolt the jacket directly to the scanner), and to also provide handles for carrying, but I had been planning to make those modifications once we received the jacket anyways. We had temperatures down to –30°C, yet the scanner and camera both remained in operational temperature ranges.”

Benefits of Pipe Heating Blankets

Pipe heating blankets from Thermaxx offer numerous benefits to clients in various industries. Some of the advantages of using our heating blankets and other insulation products include:

- Less wasted energy: Our insulation jackets help containing heat from escaping, helping you reduce electricity and gas consumption.

- Reduced damages: Your pipes will not freeze and burst or become damaged due to the cold, allowing you to avoid expensive repairs and cleanup.

- Fewer service interruptions: Fewer damaged and broken pipes means you will need to spend fewer hours getting repairs. Your entire system can stay up, running, and in commission for much longer.

- Easy removal: Our pipe heater blankets take minutes to remove and replace, making them convenient when your equipment requires maintenance.

- Increased cost savings: By saving time and energy and reduce the risk of damage which can be costly to repair, saving you money in the long run.

Our pipe heating blankets help you improve operations at your facility by allowing you to focus on your work rather than repairs.

Contact Thermaxx for Pipe Heating Blankets Today

If our pipe warming blankets sound like a suitable fit for your application, Thermaxx is ready to help. We are prepared to provide more information on Thermaxx Jackets and insulation blankets with heating elements today.

Our products are all designed and manufactured in the United States. We make custom-fit pipe heater blankets and provide turnkey installation services for organizations in several industries, including:

- Municipalities

- Schools

- Universities

- Hospitals

- Manufacturers

- Government buildings

- Commercial businesses

- Hotels

- Large offices

- Multifamily and multiuse facilities

- Industrial companies

Whether you're a local company with several branches or a national business, our high-quality insulation and pipe heating blankets can help you save money and prevent damage.

Request a quote online or contact us now to learn more about our products.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation