Cryogenic Insulation Jacket For Liquid Helium Pump

This article was written by Sam Grace, an insulation expert on the Thermaxx team

A customer contacted us about insulating a liquid helium pump, a machine designed to liquefy helium so that it can be transported throughout the machine. In order to do this, the helium must be cooled to about 4 Kelvin (-452⁰ F). Our job is to ensure that the components of the machine are insulated well enough to keep the helium at that temperature.  This was by far the coldest application we had encountered to date, so the design of the jacket was going to require some special thought.

This was by far the coldest application we had encountered to date, so the design of the jacket was going to require some special thought.

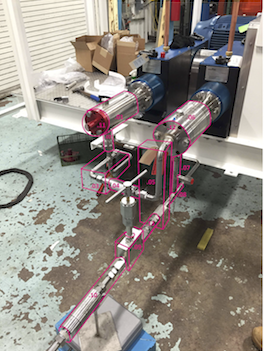

The first step in the design process is to get accurate measurements of all the different areas of the valve or machine you are covering. Sometimes these dimensions can be found using cut-sheets or 3D models and CAD drawings when available. However, these resources often don’t exist or don’t include things like mounting brackets or other job-specific obstructions that could keep the jacket from fitting. In these cases, it is necessary to send out a Thermaxx measuring team to take pictures of the valves and deliver them to the designer. This job was definitely one of those cases.

During measurement, it is important to remember to take pictures directly parallel to the piece of equipment you are measuring and the tape measure being used. Any angle between the camera and the equipment will cause what is called parallax, which results in virtually useless measurements. Keeping this in mind, our measurers take plenty of pictures detailing circumferences and lengths of the equipment, along with areas where a cutout will be needed in the jacket.

During measurement, it is important to remember to take pictures directly parallel to the piece of equipment you are measuring and the tape measure being used. Any angle between the camera and the equipment will cause what is called parallax, which results in virtually useless measurements. Keeping this in mind, our measurers take plenty of pictures detailing circumferences and lengths of the equipment, along with areas where a cutout will be needed in the jacket.

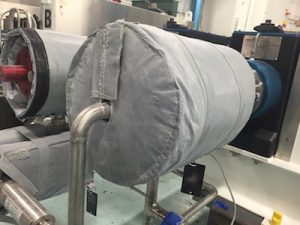

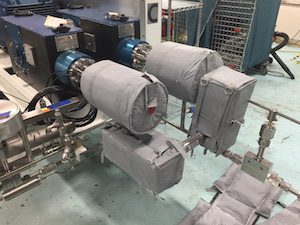

Once all the measurements are obtained, it is time to begin designing the jacket. The designer is told what materials will be used in the jacket based on the temperature of the equipment. In the case of liquid air helium, 5 layers of 10mm thick cryogel were required to keep the equipment at -452o F. This application would destroy most of the various materials we use to cover the insulation, so a special PTFE-coated fiberglass cover must be used. Using these materials, the designer decides how to best cover each piece of the equipment; either with a box pattern or a simple wrap, or in this case a combination of the two. The designer bases his patterns off of several different factors, such as ease of install and feasibility of manufacturing.

Several obstacles arose in the manufacturing of these 5-layer-thick jackets. For example, we found that multiple layers of insulation behave differently when wrapped around a pipe than just one layer of insulation. Our answer to this problem was to make each layer of cryogel slightly larger than the layer beneath it to account for the extra radial thickness. Similarly, we found that designing a flat box pattern of multiple layers was far more difficult than just one layer. We used the same method of decreasing the length of each layer to ensure that the box would fold up nicely and be able to fit on the equipment, while also being reasonably simple to install.

Several obstacles arose in the manufacturing of these 5-layer-thick jackets. For example, we found that multiple layers of insulation behave differently when wrapped around a pipe than just one layer of insulation. Our answer to this problem was to make each layer of cryogel slightly larger than the layer beneath it to account for the extra radial thickness. Similarly, we found that designing a flat box pattern of multiple layers was far more difficult than just one layer. We used the same method of decreasing the length of each layer to ensure that the box would fold up nicely and be able to fit on the equipment, while also being reasonably simple to install.

After the jacket made it all the way through production, it was checked for quality and sent to be installed. For complicated jobs like this one, we like to send just one jacket for a fit check and if everything fits well and the customer is happy, we complete the job and send all of the jackets. Our five-layer cryogenic jackets were finally ready after the first fit check and all were installed the following week. Another happy customer!

After the jacket made it all the way through production, it was checked for quality and sent to be installed. For complicated jobs like this one, we like to send just one jacket for a fit check and if everything fits well and the customer is happy, we complete the job and send all of the jackets. Our five-layer cryogenic jackets were finally ready after the first fit check and all were installed the following week. Another happy customer!

To learn more about how Thermaxx Jackets works with cryogenic insulation, contact us!

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation