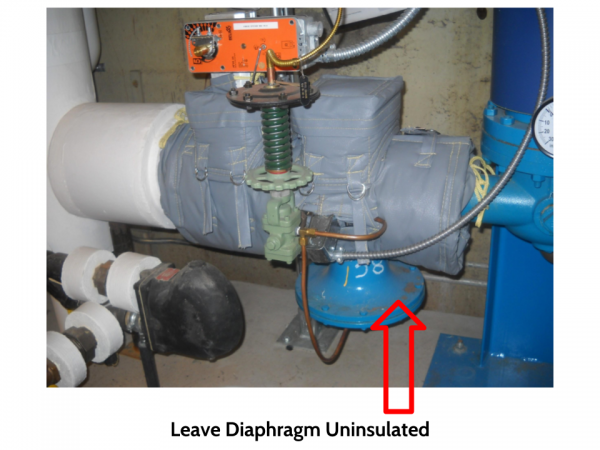

Don’t Insulate the Diaphragm of a Pressure Regulator

Why You Should Never Insulate the Diaphragm Chamber of a Pressure Reducing Valve

If you are considering insulating your steam system, remember to never insulate the diaphragm chamber of the pressure reducing valve. Indeed, the diaphragm chamber of any pressure regulator should never get insulated.

About PRVs in Steam Systems

A pressure regulator is a type of valve whose primary mission is to adjust the pressure of a medium (like steam) to meet the need of particular application, regardless of fluctuations in pressure of the substance that flows in the valve.

In a steam-using plant, steam is often generated at high pressures and reduced locally to provide heat for each steam user. The typical component used to accomplish this is a pressure reducing valve (PRV), which is, to be specific, a type of pressure regulator — though these terms are often used interchangeably. To maintain the proper outgoing system pressure, the PRV must be able to respond to changes in pressure of incoming flow: if load pressure increases by 50 psi, the valve must reduce the pressure by an additional 50 psi.

The Role of the Diaphragm in PRVs

While some pressure regulators may use only a spring as the loading element, most pressure regulators — especially steam system PRVs — utilize a diaphragm or combination diaphragm/spring. The diaphragm is a flexible membrane that responds to changes in pressure and restricts/seals flow appropriately. The diaphragm chamber is often housed underneath the valve, but can be located in different areas and positions.

Why You Don’t Insulate the Diaphragm Chamber of the PRV

In a steam system, the area below the diaphragm becomes filled with condensate as the steam in that area condenses. If the diaphragm is insulated, the temperature at the diaphragm area increases, because the insulation traps heat in that area. If the temperature increases, the pressure is artificially adjusted, and the valve may not operate as it should. If insulated, there is a chance that the condensate under the diaphragm reaches a temperature that will cause flash steam. The flash steam now requires more space than is available and will cause erratic operation of the valve at the very least, and can even rupture the diaphragm.

What is Flash Steam?

We’re glad you asked. When water has more energy than can exist as liquid at a given temperature, the water “flashes off” as a burst of steam. This can be particularly dangerous because steam occupies much more space than water. Water at 15 psig (pounds/square inch) has a specific volume of 0.017004 Cubic feet/lb.; steam at 15 psig has a specific volume of 13.75 Cubic feet/lb. The steam occupies 808.63 times the space as the water.

When the liquid flashes to steam it is like a mini explosion — the steam expands in a small, liquid filled space causing the diaphragm to flex, if the diaphragm cannot flex enough to accommodate the flash steams' requirement for “space”, it will rupture.

PRV insulation can help save your facility a good bit of money; making sure you do not insulate the diaphragm will save you a lot of trouble.

For more information, contact us!

Thermaxx Jackets

Thermaxx Jackets was founded over 25 years ago with a single purpose: to help our clients save energy with removable insulation blankets when traditional stay-in-place insulation is not practical. Our dedication to this purpose has resulted in a long list of customers who have saved money thanks to Thermaxx Jackets! Combining expertise in heat loss, wireless monitoring, insulation design, and several other disciplines, we’ve become the #1 provider and fabricator of removable insulation jackets and covers. The Thermaxx Sales and Service teams are experienced and trained to provide clients with the most timely and cost-effective solution.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation