High Temperature Insulation Materials & Applications

This article was written by Chuck Murphy, an expert at Thermaxx Jackets.

Everyday insulating materials are not sufficient for hot applications. Traditional materials used in insulating blankets, covers and jackets (silicone/fiberglass) start to falter when approaching 600°F. Cover materials start failing, threads start degrading, and insulation starts burning!

Everyday insulating materials are not sufficient for hot applications. Traditional materials used in insulating blankets, covers and jackets (silicone/fiberglass) start to falter when approaching 600°F. Cover materials start failing, threads start degrading, and insulation starts burning!

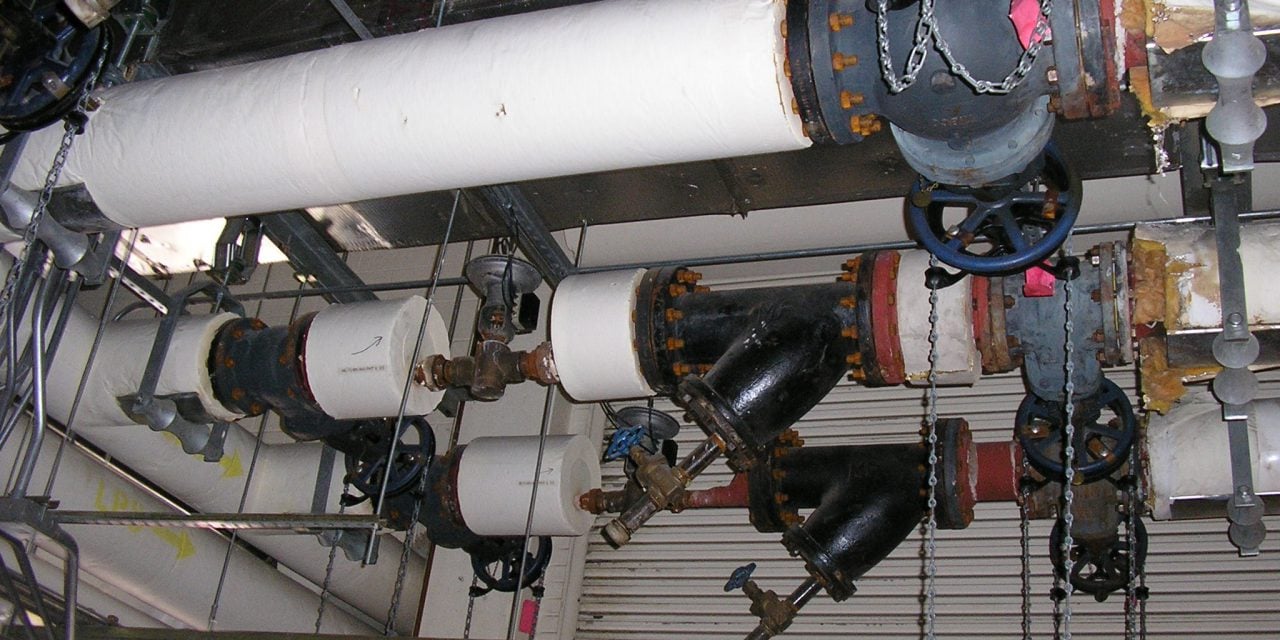

Applications that commonly experience elevated temperatures are:

- High Pressure Steam Piping,

- Valves

- Flanges

- Expansion Joints

- Heat Exchangers

- Boilers

- Furnaces

- Ovens & Kilns

- Dryers

- Turbines

- Chillers

- Compressors

- CoGeneration Plants

- Incinerators

- Industrial Processing Equipment

- Exhaust Manifolds

- Catalytic Converters

- Heat Treating,

- Welding

Thermaxx has successfully employed high temperature insulating materials for these hot situations and more. Temperatures can exceed 2200°F and require a special insulating material set to survive HOT environments. To give a feel for high temperatures, here are melting points of a few common materials:

- Aluminum 1220°F

- Brass 1823°F

- Cast Iron 2000°F

| Temp | 600°F-1000°F | 1001°F-1500°F | 1501°F-1800°F | 1801°F-2200°F |

| Materials | ||||

| Hot Side Cover | Fiberglass Cloth | Vermiculite Fiberglass | Silica Cloth | Inconel Wire |

| Cold Side Cover | Teflon Sheet | Fiberglass Cloth | Vermiculite Fiberglass | Silica Cloth |

| Hot Side Insulation | Fiberglass | Ceramic | Ceramic | Ceramic |

| Cold Side Insulation | Fiberlgass | Fiberglass | Fiberglass | Ceramic |

| Thread | Kevlar/Inconel | Kevlar/Inconel | Silica | Quartz or Nextel |

Thermaxx utilizes a program supplied by the North American Insulation Manufacturers Association called 3E+ to determine insulation type and thickness. It is a program providing standards used by insulators and utilities to determine the following:

- Perform calculations for flat surfaces and various pipe sizes

- Determine economic thickness of insulation based on fuel cost, installed cost, tax rates, maintenance, and other economic factors

- Determine surface temperature and heat loss or gain efficiency

- Calculate insulation needed for personnel protection in various design conditions

- Calculate thickness of insulation for condensation control

- Calculate greenhouse gas emissions and reductions

3E+ is used by utilities to determine energy savings and potential rebates for your insulation projects. Thermaxx offers temperature sensing systems to help track your equipment's temperatures and energy savings.

Read more about common insulation materials, or contact us to discuss your high temperature insulation needs.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation