Insulating A Thermodynamic Steam Trap's Inlet & Outlet

After years of working in the insulation industry and insulating hundreds of steam components in NYC, I've observed that there is rarely insulation on the incoming (inlet) and outgoing (outlet) piping of a thermodynamic (TD) steam trap.

This is because the facility manager will need to do maintenance on the thermodynamic steam trap assembly regularly, so using hard insulation on the components would limit his or her access to them. Also, installing hard insulation on a ½”-1” pipe can be difficult. It doesn’t make sense to use hard, non-removable, insulation when you need to have access to these components many times throughout the year for maintenance.

As a result of not insulating these components, the facility is losing a significant amount of money and energy. Especially when you consider that the TD traps are normally high pressure traps (over 300°F). Our solution? Apply Thermaxx removable insulation jackets on the TD steam trap's steam inlet and outlet, as pictured below.

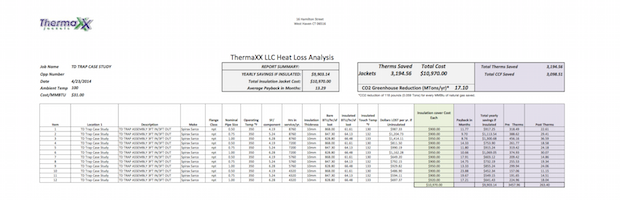

Below is a sample analysis of how much money and energy commercial customers in NYC could save by insulating the inlet and outlet of their TD steam traps.

Click to Enlarge Heat Loss Analysis[/caption]

Click to Enlarge Heat Loss Analysis[/caption]

Summary of Analysis:

- Total Project Cost: $10,970

- Total Yearly Savings: $9,903

- Payback in Months: 13.29 months

- 5 Years of Savings: $49,515.71

- Monthly Cost of Waiting: $825.26

- CO² Greenhouse Reduction (Metric Tons/yr): 17.10

- Pre Therms: 3458

- Post Therms: 263

- Therms Saved: 3195

As a result of insulating the steam inlets and outlets on your TD steam traps you will save money and energy, improve workplace safety, and reduce the ambient temperature. Learn more about our products, or contact us for more information.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation