Manufacturing Insulation Blankets In A Clean Room

So how clean is your room?! Let’s talk Clean Rooms! Exactly what IS a Clean Room and why would a manufacturing company need one?

A clean room is a separate controlled environment free of the normal ambient particles that surround us in normal daily life. The clean room is designed with a filtration system called a High Efficiency Particulate Air or better known as HEPA. The HEPA filter acts like a trap catching the tiny particles. Those particles are then filtered out. The HEPA filter has a certain design to catch particles dependent on size.

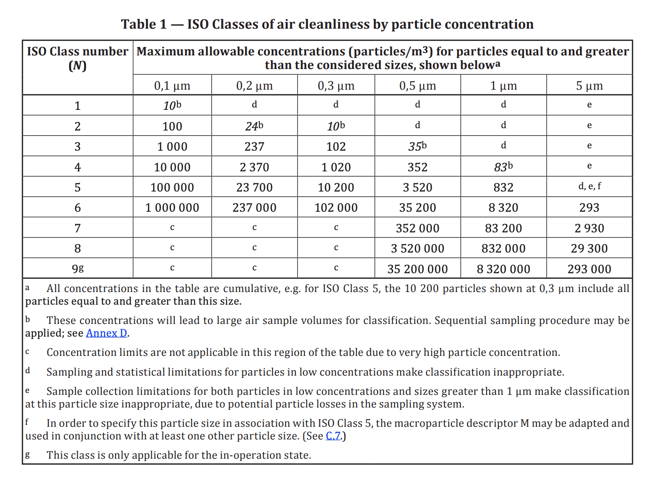

The lower the ISO class the lower the particle count and the ‘cleaner’ the room is. The filtration system controls humidity to keep the moisture out. This graph shows the different classes of a clean room. The ISO classes are based on the number of particles in the room. For example, a room with 20 hairs would be considered an ISO class 5.

So why you ask does Thermaxx Jackets have a clean room? When working with certain industries like semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy – we cannot contaminant the customer’s products. For instance, in a microchip room any particles could ruin the circuit. If we are having to clean this in a cleanroom that means the jacket is going into a cleanroom at the customers. Special materials need to be avoided as well such as silicone. At Thermaxx we use PTFE cover material and clean room compatible insulation material. For the assembly of our jackets we have a dedicated assembly area and sewing machine for the cleanroom jackets. The jackets are then brought into the cleanroom to be wiped down with lint-free alcohol wipes. Once cleaned they are heat sealed in 2 plastic bags: inner and outer bag. All of this is being done while wearing a hairnet, face mask, clean room gown and gloves. At Thermaxx we are leading the removable insulation industry by having a clean room for our customer’s needs. To learn more about our offerings, visit our products page.

So why you ask does Thermaxx Jackets have a clean room? When working with certain industries like semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy – we cannot contaminant the customer’s products. For instance, in a microchip room any particles could ruin the circuit. If we are having to clean this in a cleanroom that means the jacket is going into a cleanroom at the customers. Special materials need to be avoided as well such as silicone. At Thermaxx we use PTFE cover material and clean room compatible insulation material. For the assembly of our jackets we have a dedicated assembly area and sewing machine for the cleanroom jackets. The jackets are then brought into the cleanroom to be wiped down with lint-free alcohol wipes. Once cleaned they are heat sealed in 2 plastic bags: inner and outer bag. All of this is being done while wearing a hairnet, face mask, clean room gown and gloves. At Thermaxx we are leading the removable insulation industry by having a clean room for our customer’s needs. To learn more about our offerings, visit our products page.

Rose Titcomb - Account Manager at Thermaxx

Rose Titcomb comes to Thermaxx as our Northwest 2018 sales partner. Having grown up in the city by the Bay, San Francisco, she understands the importance of community. That community feeling has driven her to play team sports and run a business for half her career. She has ties to the East Coast from the mom and pop store her grandfather owned in upstate New York to her schooling days. She is excited to embrace a new venture she believes is a valuable tool for many businesses with the Thermaxx family and looks forward to the new relationships she will make. In her free time Rose loves’ #1 loves are her children. You may also catch her hitting the ball around and eating her way thru the windy city by the Bay.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation