Removable Insulation Cover: 5 Types of Closures, Which Should You Choose?

Depending on the type of removable insulation cover your piping system requires will normally be the final determinant as to what type of closure you choose. However, it is still important to know the in’s and out’s of various closure types when making such a decision. Five types of closures are double d-ring, Velcro, drawstring, snap, and custom-made. The one thing these 5 types of closures have in common is that they are all used on removable insulation to secure it.

1) Double D-ring- As the most heavy duty form of closure, double d-rings are basically metal rings that bolt down your insulation covers. This form of closure is most often used when the equipment being covered is at extremely high or low temperatures or is in constant intense motion. Using a double d-ring will help prevent your cover from coming lose during your piping system’s operation. Since it is meant to keep your insulation cover on, removing a cover with double d-rings is more difficult than other forms of closure. It can be removed, but not with the same level of ease as Velcro or snap closures.

1) Double D-ring- As the most heavy duty form of closure, double d-rings are basically metal rings that bolt down your insulation covers. This form of closure is most often used when the equipment being covered is at extremely high or low temperatures or is in constant intense motion. Using a double d-ring will help prevent your cover from coming lose during your piping system’s operation. Since it is meant to keep your insulation cover on, removing a cover with double d-rings is more difficult than other forms of closure. It can be removed, but not with the same level of ease as Velcro or snap closures.

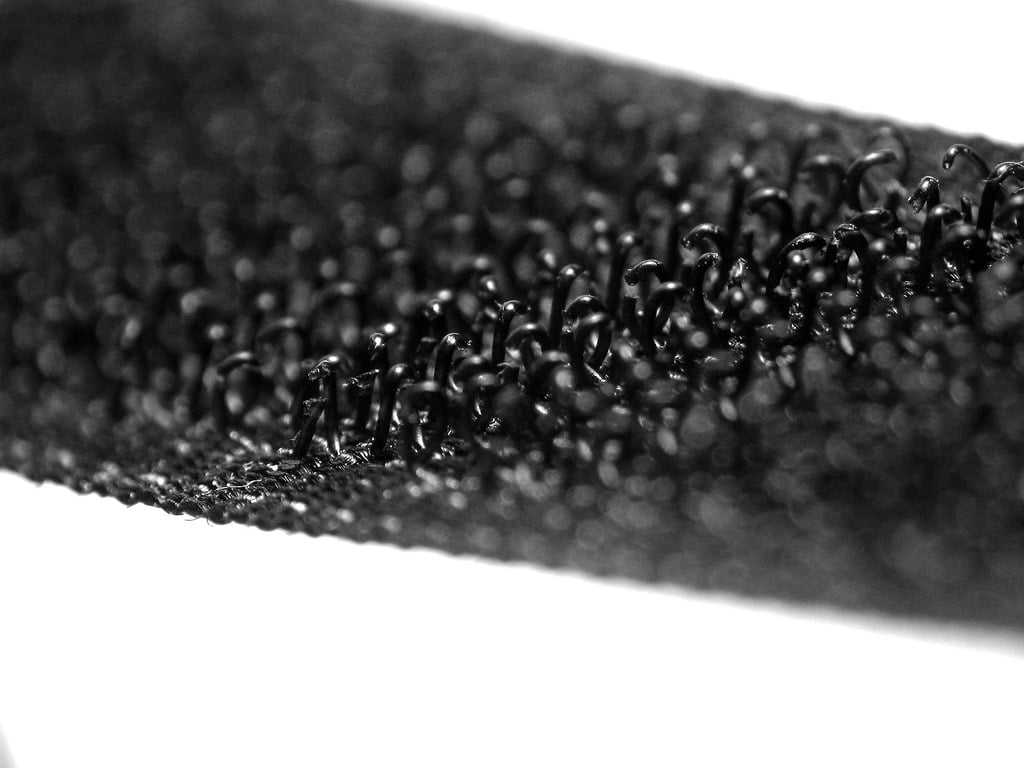

2) Velcro - This type of closure can certainly be used for a multitude of insulation covers. It is most helpful when covering equipment that isn’t hazardous to operators working around the machinery. Velcro closure systems are often used because they can be easily be opened or closed to perform maintenance or expansions on your existing equipment. Since Velcro is so easy to remove, it’s important that the equipment doesn’t reach extremely high or low temperatures that could injure workers if the covering were to come off at an unplanned time.

3) Drawstring- Using this form of closure is also fairly common because it is so easy to use. The drawstring plastic clasp can quickly and easily ensure the removable insulation cover will stay on your equipment, guaranteeing continued safety in the workplace. There’s no longer a need to tie a knot, which makes the drawstring that much easier to use when securing your insulation cover.

4) Snap- Removable insulation covers cover many different types of equipment, some that work better with having a snap closure. A snap closure is where your removable insulation has multiple snaps throughout the cover, which holds the cover closed as the equipment operates. These snaps also allow for easy removal of the insulation cover. Snap closures can help with equipment with extremely low temperatures, but isn’t as helpful with securing equipment that reaches extremely high temperatures. Depending on the material of the snap, they can warp or melt at certain high temperatures.

5) Custom-made- Some insulation covers, often like the equipment they cover, are extremely unique and need to be tailored to a specific circumstance. Some covers might require a Velcro closure, alongside snap closures or any combination of the various kinds of closures. This might be one of the best ways to ensure your removable insulation covers open and close with ease, while keeping your equipment completely snug and effective.

Thermaxx Jackets

Thermaxx Jackets was founded over 25 years ago with a single purpose: to help our clients save energy with removable insulation blankets when traditional stay-in-place insulation is not practical. Our dedication to this purpose has resulted in a long list of customers who have saved money thanks to Thermaxx Jackets! Combining expertise in heat loss, wireless monitoring, insulation design, and several other disciplines, we’ve become the #1 provider and fabricator of removable insulation jackets and covers. The Thermaxx Sales and Service teams are experienced and trained to provide clients with the most timely and cost-effective solution.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation