Insulating Ammonia Refrigeration Systems

Insulating Ammonia Refrigeration Systems can save a tremendous amount of Energy Dollars!

Please use extreme caution when working on or around an Ammonia system. Ammonia is both caustic and hazardous in its concentrated form. It is classified as an extremely hazardous substance in the United States.

Ammonia is a compound of nitrogen and hydrogen, or NH₃. Because of Ammonia’s vaporization properties, it is frequently used as a refrigerant. NH3 boils at −33.34 °C (−28.012 °F) at a pressure of one atmosphere, Ammonia was commonly used before Freons (chlorofluorocarbons) became popular.

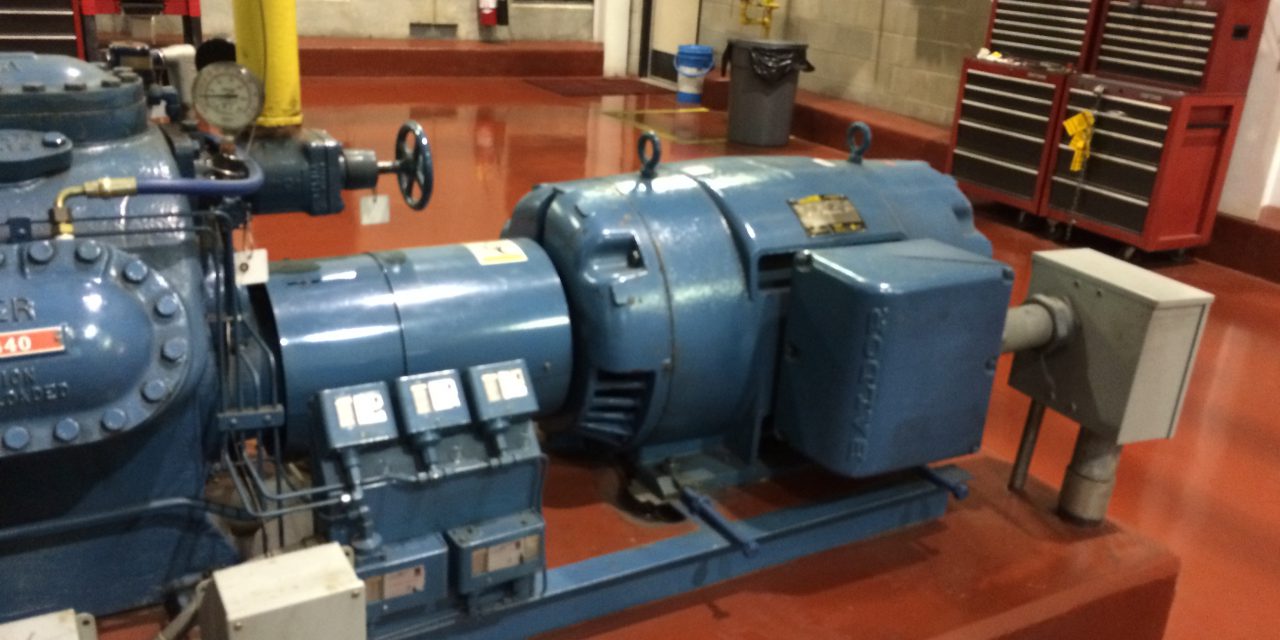

The operating temperature of these ammonia systems varies between -50°F and 50°F. Refrigeration implies removing heat from a low-temperature reservoir and transferring it to a higher temperature reservoir.

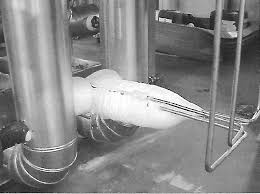

Ice on refrigerant suction piping Ice on refrigerant suction piping |

To remove heat from air or water at the application requires a significant amount of energy. That energy can be in the form of steam or electricity. Regardless, heat gain in the piping system wastes thousands of dollars per year. Many times visiting hospitals, refineries, chemical plants or large refrigeration facilities we see components in a piping system that look like a huge block of ice!

What causes the ice? As the ambient air flows across the cold component the specific volume of the air decreases. As the specific volume of air decreases humidity (moisture) in the air as a gas must now change phase to a liquid. The “water” on the refrigerant piping system is now subjected to temperatures below 32°F, ice forms, and forms and forms and forms until we have a huge block of ice!

Ice on ammonia piping Ice on ammonia piping |

How can this waste be significantly reduced? Proper insulation installation. New insulations have replaced most fiberglass installations. Aerogel insulation is the most thermally efficient solid insulation available. One product, Cryogel-Z manufactured by Aspen Aerogels, is our first choice for any cold application. A very important characteristic of a good insulation system for cold applications is the “Vapor Barrier.” It resists the ingress of water vapor toward a cold operating system. Cryogel-Z has an integral vapor barrier. For every layer of Cryogel-Z insulation a vapor barrier is present.

Valves, piping that must be inspected for CUI (Corrosion Under Insulation) and other components must be insulated properly. Insulation thickness, insulation type and other factors need to be considered. Contact the experts at Thermaxx Jackets and let them determine the appropriate insulation system for you!

Thermaxx Jackets

Thermaxx Jackets was founded over 25 years ago with a single purpose: to help our clients save energy with removable insulation blankets when traditional stay-in-place insulation is not practical. Our dedication to this purpose has resulted in a long list of customers who have saved money thanks to Thermaxx Jackets! Combining expertise in heat loss, wireless monitoring, insulation design, and several other disciplines, we’ve become the #1 provider and fabricator of removable insulation jackets and covers. The Thermaxx Sales and Service teams are experienced and trained to provide clients with the most timely and cost-effective solution.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation