Pipe Insulation and its Contribution to Asset Management

This article was written by Brian Bannon, Owner of Thermaxx Jackets

I have been in the insulation business for 30 years. Not much has changed in those 30 years. Materials have changed very little. Tools used to install insulation have not changed at all! And the reason to insulate mechanical piping has gone unchanged as well: Because we are supposed to.

What about insulation that can help with Asset Management?

If you asked me that question 5 years ago, I would have looked at you like you had two heads! Today, the answer is absolutely!

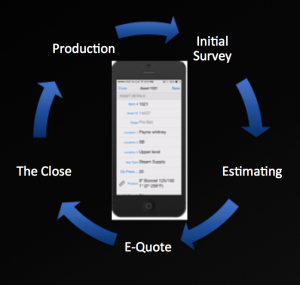

In 2014 Thermaxx partnered with the Slate Pages, LLC. We were looking for a way to individually tag our removable insulation jackets so we could track them through the sales, production & install process.

Phase 1: Develop an iOS App

We first developed an Apple App that would allow our sales team to build a project and sync it with our internal system to capture data / images to each mechanical asset that required insulation. Once sync’d, our estimating department could accurately quote the project for client submission.

Once the project was awarded, unique Slates were printed and sent to production. The slates were actually the embryo of the insulation jacket. The designers scan the slate, see the component information and photos, then design the jacket. The slate is then sent to production for manufacturing. Each production station scans the slate as the removable insulation is manufactured. This allows accurate tracking of the Jacket throughout production and keeps track of it’s location. When the jacket is installed, the installers use the app to photograph the insulated component.

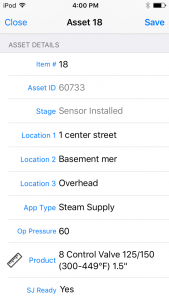

When the jacket tag (slate) is scanned with a QR code reader on any smart phone, the following information appears:

- Item Number

- Location Information

- Application Type

- Operating Pressure

- Component Type

- Component Size

- Jacket Min Max Temp

- Insulation Thickness

- Jacket material Hot Side

- Jacket material Cold Side

- Pre Photo & Post Photo

- Pattern

This is all great information to have. Thanks to the Internet of Things (IoT), insulation is now in the cloud! The clients loved having the information right on the insulation. But what they really cared about was the component that was insulated. They wanted to know things like, when was that insulated steam trap inspected? What is the valve manufacture and when was the last time that valve had service?

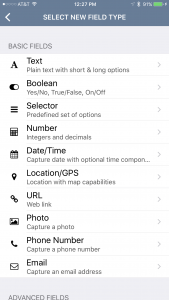

Phase 2: Develop the Asset Management portion of the App

Thermaxx and Slate Pages worked on phase 2. Give the end user the ability to add fields and update the information on the slate. This would allow the mechanics to keep track of their maintenance history, on the valve, at the valve! Step 1 was to decide what fields could be added. We started out with this simple list.

When the insulation project is complete, customers download the free Slate App from the app store and are given an authentication code to allow for Slate edits of the asset tag.

One of our first clients added a simple URL field and pasted in the website that listed the valves operating manual. This allowed them to scan the tag and have instant access to the valve manual without leaving the work area or searching their phone for it. Another client listed their contact phone and email on the tag which instructed anyone working on that particular valve to contact them for special instructions. He have also had large out door facilities add a GPS location field so they can view there valves in a map view. The possibilities were endless!

Phase 3: Develop a Journal Field that saves history by Day/Time/User

Our newest field was the Journal field. This is the game changer. Customers can now track maintenance notes or tasks similar to a blog. When the Slate is scanned, a history of the valve maintenance information is displayed. Additionally, clients can insert multiple fields into a journal field and create a pre start or inspection check list.

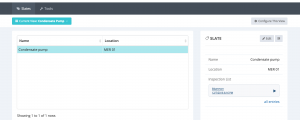

In this example the mechanic was inspecting a condensate pump. A pre written template has him/her inspect 5 items with a note section to leave notes.

The next time this pump is inspected, the inspector will be able to leave his/her own notes and view the history of notes.

Phase 4: Develop Web Portal

Having the information on your IPhone and on the tag was awesome. Having it there and on a web portal at your desk would be amazing!

Thermaxx then developed a web portal so the information scanned at the asset is saved not only on the phone and slate, but on a web portal.

The release of the web portal completed the package. Admin teams or end users can also update, view and sort the information from the comfort of their office.

The Thermaxx Smart Jacket is now in hundreds of facilities across the country. Contact me to learn more!

Brian Bannon

Director

Thermaxx Jackets

bbannon@thermaxx.es

Brian Bannon - Vice President of Thermaxx

Brian Bannon, Vice President of Thermaxx, started his career in construction, insulation & demolition. While performing undergraduate studies at the University of CT, Brian & family formed an environmental clean up company in New England. His vision, dedication & drive helped take this company from a garage startup in 1986 to a $25 million dollar a year CT icon. A life long entrepreneur, Brian has started and driven many companies to reach their revenue and performance goals.

Categories

- removable insulation

- thermaxx jackets

- energy savings

- savings

- energy efficiency

- safety

- pipe insulation

- energy

- case study

- insulation materials

- thermal insulation

- heat loss survey

- heat loss

- energy loss

- hot insulation

- fiberglass

- installation

- steam

- New York

- custom insulation

- NYC Case Study

- boiler

- university

- Connecticut

- reusable insulation